Colab Carbon delivers for High School Robotics Team

Showing the next generation of enthusiasts what the industrial 3D printing industry can bring to solving the latest engineering challenges is key to sustaining the momentum for creating new and innovative solutions for the future. When we were approached by the high school we jumped at the opportunity to produce the parts for the Georgia FIRST Robotics Competition.

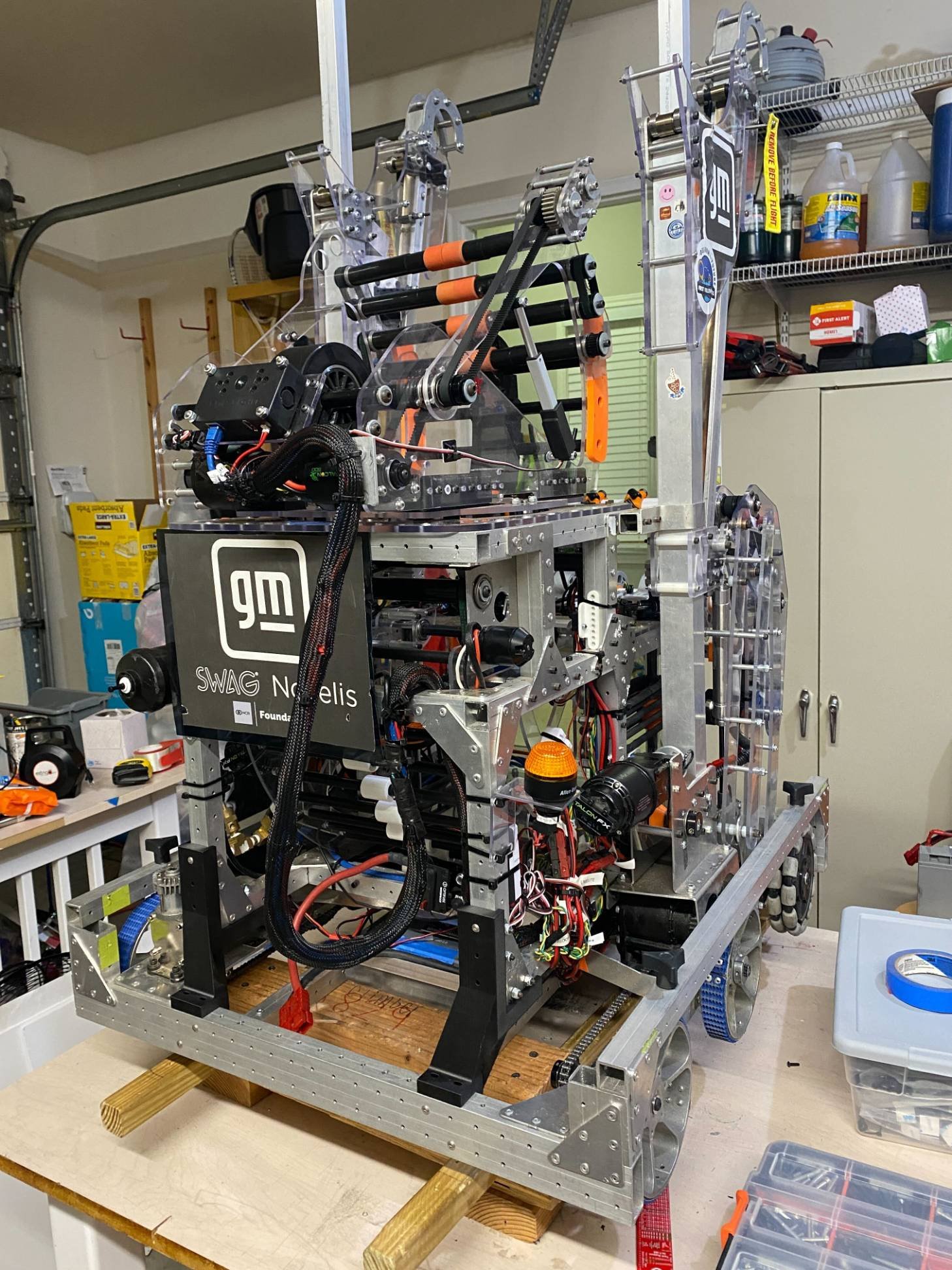

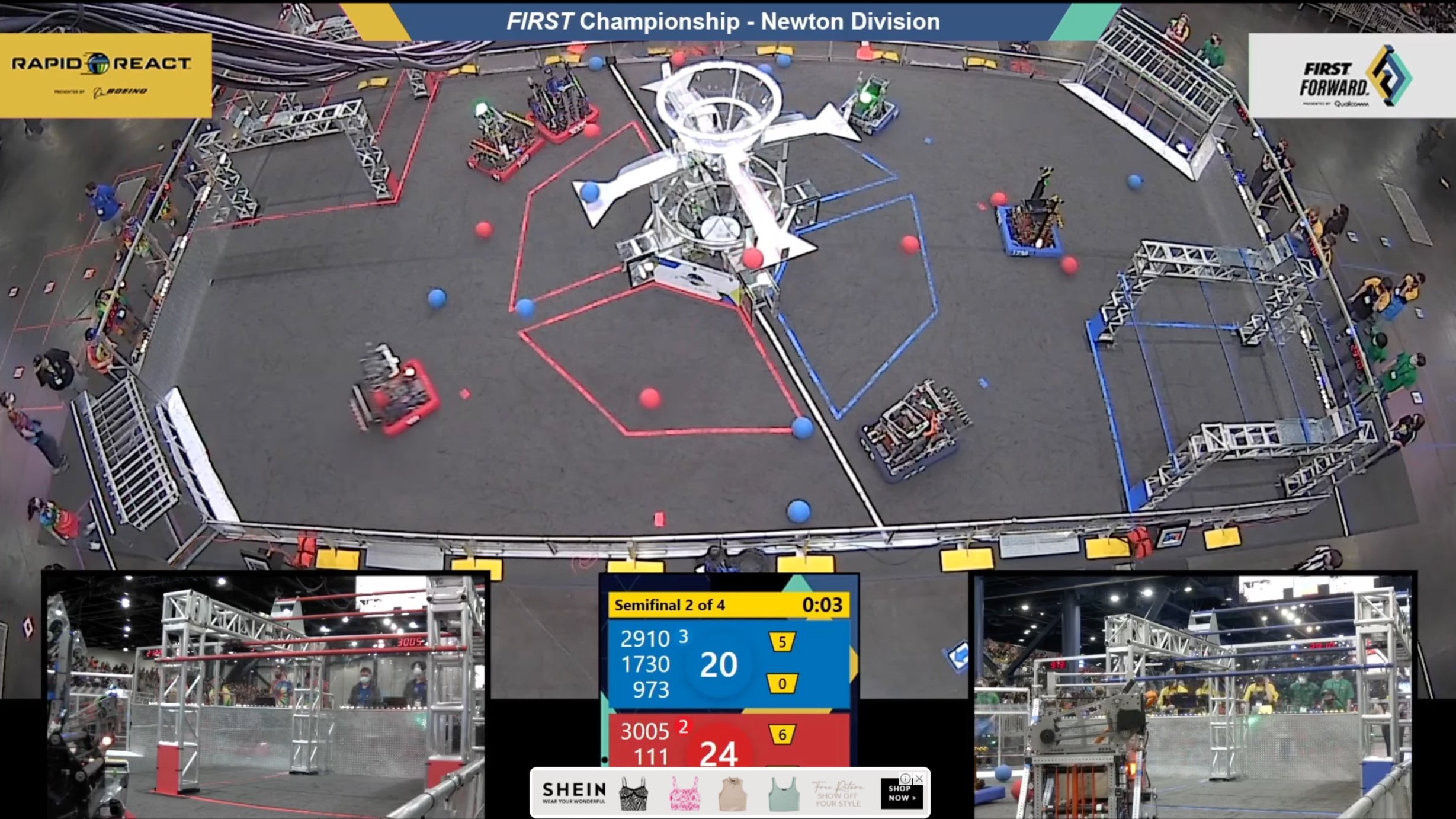

This robot is designed to compete in an arena with other robots that shoot colored balls into a goal autonomously and later climb a ladder structure.

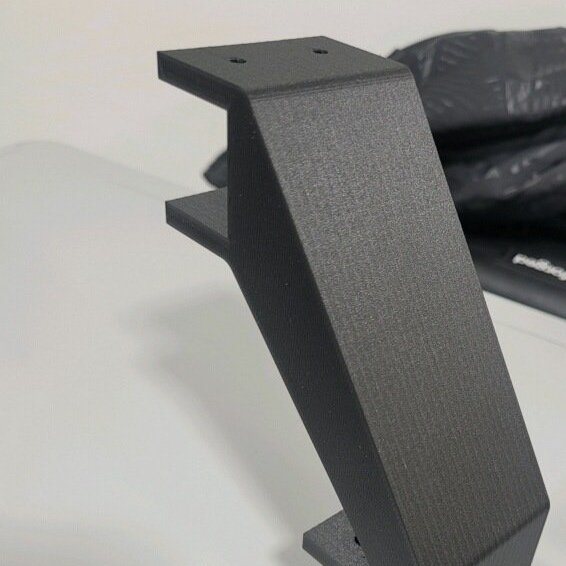

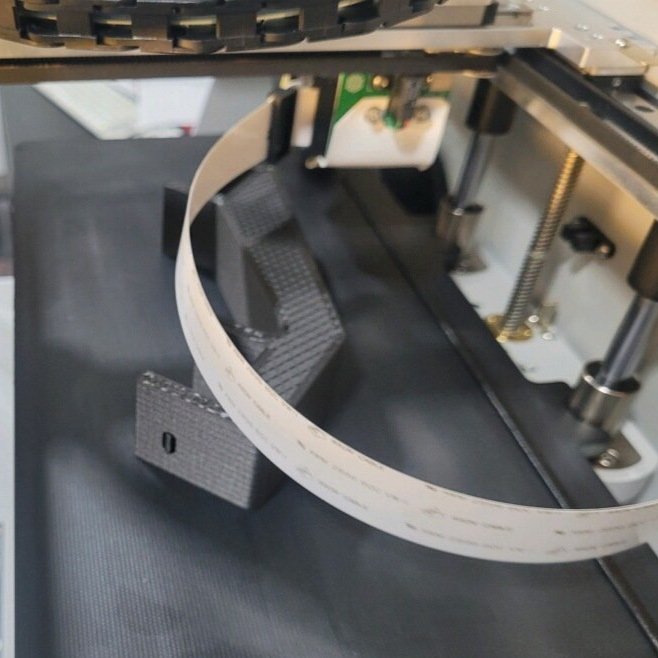

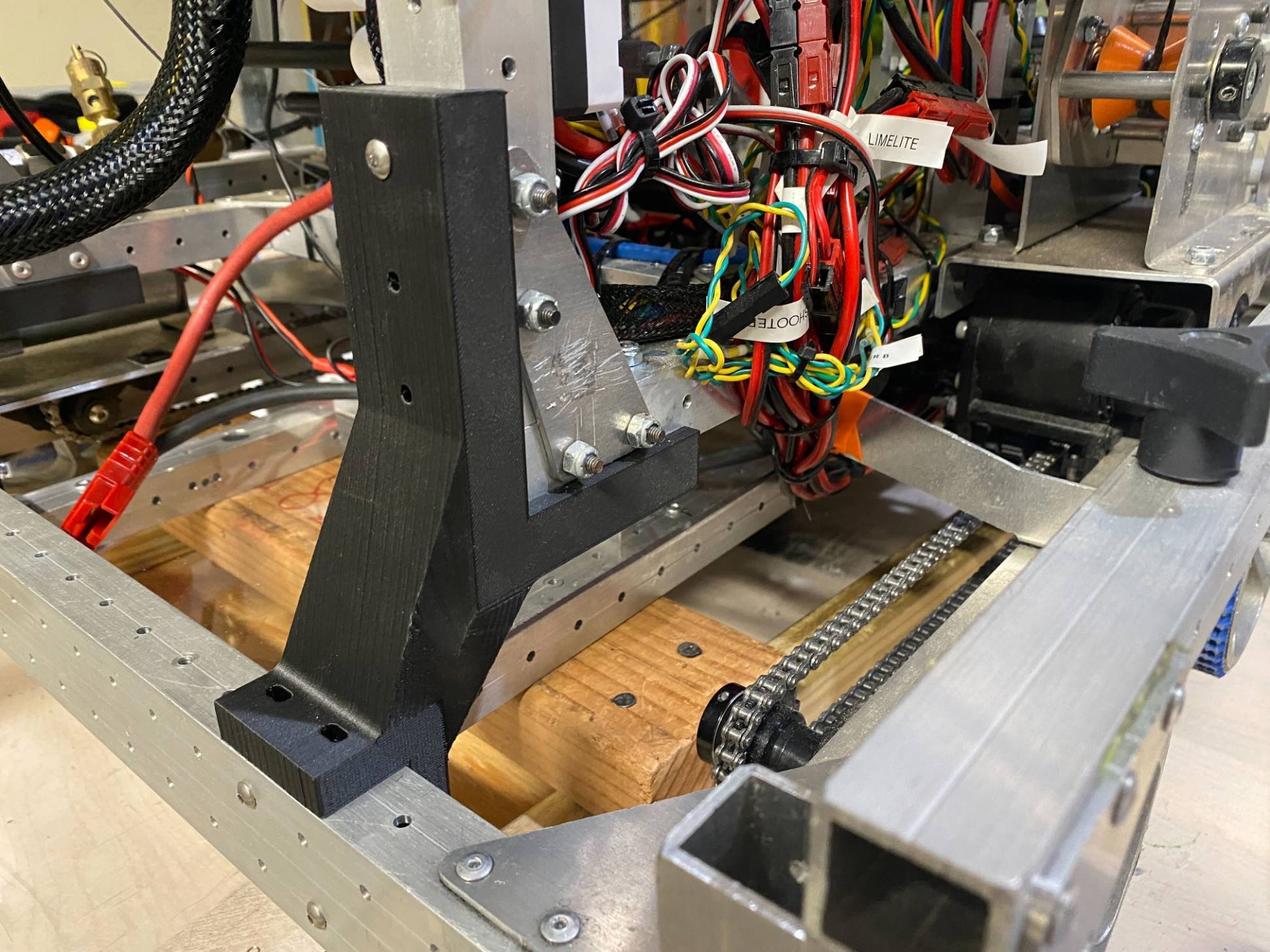

The first design of the robot used aluminum alloy to connect the base structure to the body of the robot. The team discovered that the aluminum parts were bending during testing which would limit the robot’s capabilities. Our Colab Carbon Composite Material when engineered properly is as strong as 6061 aluminum alloy but will retain its original shape when load is allied in various directions.

When competing with battle style robots you can also expect to take on some damage at the event. Colab Carbon took a beating but ultimately withstood the test and helped deliver the robotics team to a 3rd place finish at the GRITS event in October 2022!

We are always looking for new opportunities to leverage our industrial 3D printing technology to solve problems not in the high performance automotive industry but in all kinds of innovative ways! Thank you for the opportunity to show off what Colab Carbon can do in extreme and unique circumstances. Reach out to us if you have a project where you think Colab Carbon can help deliver on your goals.