High-Performance 3D Printed Automotive Parts

Advantages of 3D Printing in the Automotive Industry

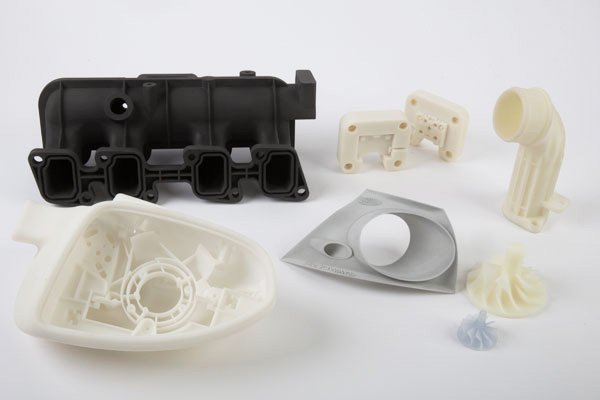

3D printing in the automotive industry is not new, in fact, it has been used for the past few decades. Current methods of 3D printing are used to create and test automotive prototypes for form and fitment before using more traditional means to produce the final product. Additive manufacturing is a term we use to describe 3D-printed parts. In the automotive industry, this provides design teams the ability to quickly try multiple iterations of parts at relatively low cost. This engineering approach brings more flexibility, resulting in a much more efficient way to evolve your product multiple times before bringing it to the market.

Why Stop at Prototyping?

As mentioned above, traditionally this is where 3D printing has stopped, at the prototype phase…. However, there is a growing trend for smaller manufacturers to be able to deliver a 3D-printed end-use part. These parts would still be high enough quality to meet or even exceed what a machined part could deliver at a lower cost and in a fraction of the time. When we looked in depth at the motorsports industry, we saw a huge opportunity to deliver extremely functional parts on a scale that traditional subtractive machining methods just can’t compete with. Colab Carbon is our answer to the high-performance industry looking for unique solutions to solve common problems on all types of vehicles.

Not Your Average Hobbyist 3D Printing Solution

Now before the pitchforks come out…. There is absolutely a place for hobbyist machines in the automotive space. This is where innovation comes from, enthusiasts! With the accessibility to purchase your own machine and use incredible low-cost CAD software like Fusion360; the grassroots racer can bring a concept to life in his garage for minimal investment. But when it comes to producing higher volume and higher quality end-use parts, you really need to be in the industrial space for additive manufacturing. Industrial printers not only print with much greater resolution and accuracy, but they can also print with a vast array of materials including carbon fiber, kevlar, nylon, and fiberglass just to name a few. The ability to 3D print highly accurate automotive parts that are as strong as aluminum and withstand the rigors of motorsport in terms of heat and vibration is a game changer.

Where Can You Find 3D-Printed Parts in Racing?

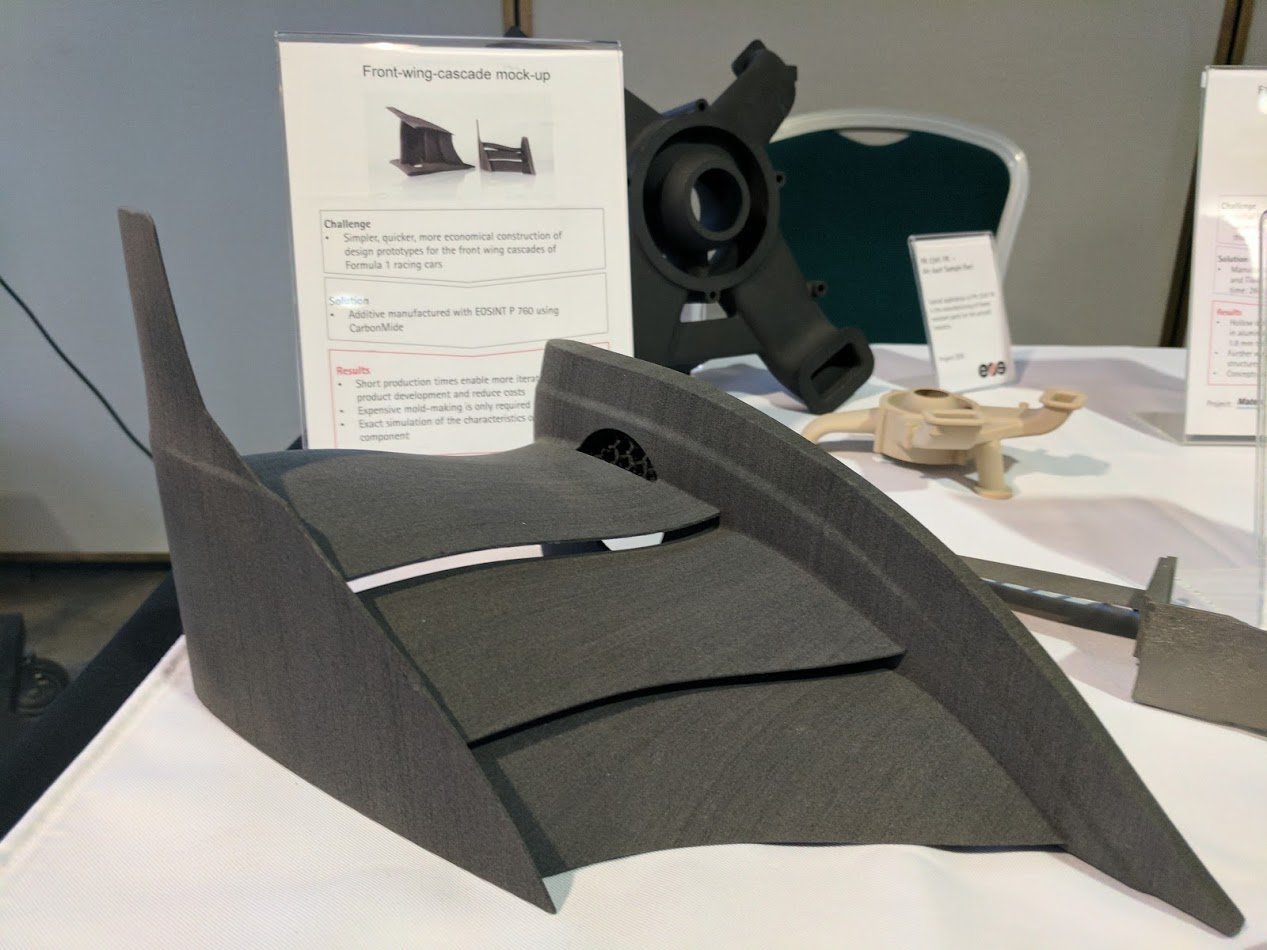

Take a look around and you will find additive-manufactured (AM) parts at the highest levels of motorsport. The ability to produce one-off racing parts has become a vital application for 3D printing in this space. You can even find 3D-printed parts in Formula 1! Motorsport engineers have long proven 3D printing for rapid prototyping to be a useful tool in a sport where aerodynamics and packaging constraints can change from season to season and track to track. 3D printing has helped race teams achieve lighter-weight parts that increase speed, fuel efficiency, and better engine performance for reduced wear and tear.

What is Colab Carbon?

The Colab Carbon composite parts line leverages state-of-the-art materials and machinery, which we believe is the future of additive manufacturing within the motorsports industry for end-use parts. Everything is designed and manufactured in-house which allows us to move quickly from concept to reality in a matter of days. More traditional manufacturing techniques would take much longer and would not allow for multiple iterations and limited production runs. Colab Carbon material is a nylon-based chopped carbon that has been stress tested to sustain 325°F and is extremely chemical resistant to engine oil, fuels, brake cleaner, and even acetone. We then take it a step further by adding continuous carbon fiber strands to various areas of the part that requires added strength. When designed properly, the end result is a part that rivals aluminum in terms of strength and durability.

Where Can You Find Colab Carbon Today?

For the initial launch of Colab Carbon, we focused on what we found to be a very underserved market for motorsport - the mounting of various components on vehicles. Often times sensors are mounted with zip ties, Adel clamps, crude brackets, etc. We saw this as an opportunity for Colab Carbon to deliver high-quality and lightweight solutions that will hold up to the stresses of racing. You will find solutions for pressure and temperature sensors, flex-fuel sensors, and Mac Valves (boost control solenoids), just to name a few. Line and hose retention is also something that is often overlooked in a race car. We have developed several engineered solutions for line and hose clamps that can be custom sized to your specific requirements. We have even gone as far as 3D printing key components of our R8 and Huracan removable parachute system using Colab Carbon to deliver parts that would be cost-prohibitive to otherwise machine on a traditional CNC at lower production volumes.

What is the Future of Additive Manufacturing with Colab Garage?

Colab Carbon is just the beginning for 3D printed additive manufactured parts. We have already seen the need to grow our expanding parts line well beyond what is currently available today with our in-house developed parts. Our design team is working vigorously to develop new solutions that are brought to us by you, the racing community. As part of that effort, we are also working with several other shops in the industry to provide design, engineering, and production services for their own line of 3D-printed end-use parts to the industry. Additive manufacturing (AM) is here, it is only growing in motorsport, and we cannot wait to see what the future holds for Colab Carbon.